Atacama large millimeter array telescope

About the photo

I can't really say much about this photo because I found it at this website www.nrao.edu

http://www.asiaa.sinica.edu.tw/project/alma.php but it does look quite amazing. I never had the chance to visit ALMA but maybe that's a good thing because I don't do so well at altitude. The highest place I've been is here at Maunakea which is 4,200 m and ALMA is situated at 5,000 m. Egad!

My involvement

I became involved with the ALMA project back in 2009 to work on the Alternate Laser Synthesizer in collaboration with NRAO and consultation with NAOJ. This work produced a follow on project to develop a LO Reference Test Module for testing the ALMA receivers at EA-FEIC.

engineering activities

Testing MZM-LORTM with Band-1 Cartridge

MZM-LORTM Modification to Support Band-1

2014 - Initial MZM-LORTM unit testing with ALMA Band-1 WCA in Taipei. Left and right photos are of the LORTM unit and WCA, respectively. Official testing of the Band-1 cartridges were performed at EA-FEIC in Taichung. The LORTM unit itself mounts onto a tilt table along with the cartridge under test within a thermally control chamber (D. Kubo, R. Srinivasan).

MZM-LORTM Modification to Support Band-1

MZM-LORTM Modification to Support Band-1

2014 - I procured the components for the modifications in Hilo and Ranjani and I flew to Taipei to perform the upgrade in one of the labs. The above photo was taken shortly after the modifications were completed and we were verifying its operation prior to interfacing to the Band-1 WCA in the lab next-door (D. Kubo, R. Srinivasan).

User's manual updated for Band-1 modification:

https://www.dropbox.com/s/48rcksrsd8j73m9/Memo_RS_2014_MZM_LORTM_Op_Manual_Revision_E.pdf?dl=0

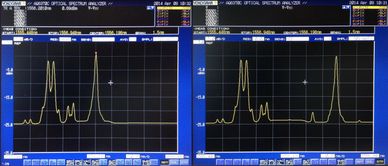

MZM-LORTM Optical Output Spectra

MZM-LORTM Optical Output Spectra

2014 - Left panel - Optical output spectra for Band-1 on left with tones at 192.698, 192.692, and 192.644 THz. Right panel - Bands 2-10 mode with tones at 192.698, 192.692, and 192.592 THz.

The Backend Signal Test Source locks to the difference frequency of the outer pair of tones and for the Band-1 case would be 54.0 GHz. This 54 GHz CW tone is radiated into the cartridge under test. The WCA locks to the difference frequency between the inner pair to generate an LO frequency of 48.0 GHz. The resultant IF produced by the cartridge under test is 6.0 GHz and is amplitude/phase compared to a reference IF to characterize the performance of the cartridge (D. Kubo, R. Srinivasan).

MZM-LORTM FBG Assembly

MZM-LORTM Optical Output Spectra

2014 - Closeup view of optical circuitry. The blue component on the upper plate is SW1 SPDT optical switch used to introduce the optical carrier with duel tone on the LSB. Just visible at the bottom foreground is a portion of MZM device (gold) that utilizes a TE cooler to transfer 1.5 W of heat to the deck plate (D. Kubo, R. Srinivasan).

Unit schematic:

https://www.dropbox.com/s/6ybbi6des5c0ec8/MZM-LORTM_block_2014apr13.pdf?dl=0

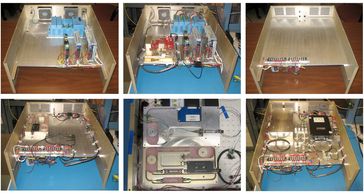

Completed MZM-LORTM

2011 - Left and right are bottom and top views of unit with front panel removed. All optical components, with the exception of the TeraXion laser, were isolated to the top deck without any air convection. Cooling of the active optical components were strictly via conduction through the deck plate. The active RF components, power supplies, and the deck plate itself were convection cooled using two rear panel mounted fans with exhaust vents located at the opposite end on the front panel with the intention to produce laminar air flow (design/test - D. Kubo, C.C. Han, R. Srinivasan).

In addition to the hardware development, an intensive effort was put forth by Ranjani to integrate her software code to the existing Labview software that was used for the official acceptance tests (R. Srinivasan).

Description of the unit on the ASIAA website:

https://www.asiaa.sinica.edu.tw/gallery/show.php?i=d26da3f5e0870bf0e0d94e5ddec8598c

Poster:

https://www.dropbox.com/s/efjljkgfu4ennqn/MZM_LORTM_poster_2012mar9.pdf?dl=0

2011 summary report for LORTM and LS:

https://www.dropbox.com/s/731sf6dtwi0v63w/ALS%20develop%202011feb12c.docx?dl=0

MZM-LORTM Under Assembly

2011 - Front view of unit during assembly in my office with my wife visiting me! This effort to integrate the delicate optical components in a fashion that would meet the Allan Variance phase stability requirements was probably one of the most challenging assembly tasks I've been involved with. Looking back at it I think to myself that it was beyond my abilities. A proper thank's to Johnson for helping me remotely in fabricating adapter plates when I needed them (D. Kubo, C.C. Han).

Description of design upgrade:

https://www.dropbox.com/s/boy80vl36bu99a5/MZMLORTM%20Upgrade%202011jul13.ppt?dl=0

MZM Laser Synthesizer Testing at NRAO

MZM Laser Synthesizer Testing at NRAO

MZM Laser Synthesizer Testing at NRAO

2010 - Integration of the MZM Laser Synthesizer (black) unit into the ALMA Central LO system. The two units above ours are the TeraXion Laser Synthesizer which was based on a different design approach of using slave lasers (D. Kubo, R. Srinivasan, H. Kiuchi - NAOJ, W. Shillue - NRAO).

Condensed summary - Our approach to generate two optical tones separated by the desired reference frequency produced significantly improved LO phase noise performance over the baseline design. The ALMA Line Length Corrector, system, however, was designed to operate with a fixed master laser and was incompatible with our design.

2013 IEEE journel article:

https://arxiv.org/abs/1803.08174

Completed MZM Laser Synthesizer

MZM Laser Synthesizer Testing at NRAO

MZM Laser Synthesizer Testing at NRAO

2010 - I spent a little extra effort on the exterior of the unit since it represented ASIAA's product development. All signal and power I/O interfaces were via the rear panel. Cooling was achieve by two 24V DC fans drawing air into the unit below the deck and circulated around the front to the upper deck and exhaust out of the rear panel through quasi EMI screens (hardware - D. Kubo, software - R. Srinivasan).

Description of the unit on the ASIAA website:

https://www.asiaa.sinica.edu.tw/gallery/show.php?i=9e527ecac99c29a1b9ccfa57229661bd

Design report:

https://www.dropbox.com/s/tvyq5r2fe0tejos/MZM_LS_development%202011feb11.ppt?dl=0

Completed MZM Laser Synthesizer

MZM Laser Synthesizer Testing at NRAO

MZM Laser Synthesizer Assembly Sequence

2010 - Left and right are top and bottom views of the unit, respectively. The unit accepts a low phase noise RF reference signal from a Keysight E8257D synthesizer over a range of 13 to 31 GHz. This RF signal is amplified to produce +27 dBm (0.5 W) drive into a Mach Zehnder Modulator (MZM) and provides intensity modulation of a narrow line width maser laser at 1556.21 nm through the process of interference.

The MZM also accepts a DC bias to alter its operation mode. Null-bias mode produces two optical outputs spaced by twice the input reference frequency and suppresses the central master laser. Full-bias mode produces a pair of optical signals separated by four times the input reference frequency but does not suppress the master laser. The master laser is suppressed with the use of an FBG filter. Together, these two modes cover an output frequency range of 27 to 124 GHz (hardware deign - D. Kubo, H. Kiuchi - NAOJ, software design - R. Srinivasan).

MZM Laser Synthesizer Assembly Sequence

Component Testing of MZM Laser Synthesizer

MZM Laser Synthesizer Assembly Sequence

2009 - Starting at the upper left, the photos with the two rear panel mounted fans denote the bottom deck with DC power supplies, ADAM-5000 four slot TCP/IP controller (blue device), Centellax RF power amplifier (red circuit board), and Sumitomo Osaka Cement MZM device..

The 3rd photo on the upper row shows the top deck with exhaust vents on the rear panel and voltage regulators and DC terminal strips on the front deck edge. An aluminum subassembly housing, center photo of bottom row, was designed to house the majority of the optical components. The black device is a variable gain EDFA controlled an analog voltage produced by the ADAM controller.

In hindsight from our LORTM experience described above, I would do a few things differently if I were to have a second go at it. One would be to isolate all optical components from air convection as they are very sensitive to even minute changes in temperature (D. Kubo).

MZM Laser Synthesizer Early Layout Phase

Component Testing of MZM Laser Synthesizer

Component Testing of MZM Laser Synthesizer

2009 - The mechanical packaging of this unit was based the concept of an optics table with threaded holes to accept a variety of optical and RF components. For this design, however, I used aluminum instead of steel to reduce weight but gave up the ability to fix items to the deck using magnets. The M3 holes are spaced by 20 mm and penetrate the deck for use on both sides. In addition to being a universal mounting plate, the deck serves as the primary conductive heat sink for thermally dissipative devices.

For the chassis, I selected Par-Metal which sells a variety of fully EMI compliant kits at a very reasonable price and it typically costs more in labor to fabricate the openings for I/O and cooling. Nearly all designs generated by my colleagues and myself utilize this general concept that was originally developed for this project (D. Kubo).

Component Testing of MZM Laser Synthesizer

Component Testing of MZM Laser Synthesizer

Component Testing of MZM Laser Synthesizer

2009 - This effort to develop the MZM based Laser Synthesizer in collaboration with NAOJ was initiated by Ming-Tang who is our director for the Hawaii office. At that time, NRAO had subcontracted TeraXion to develop the baseline Laser Synthesizer but was encountering difficulty meeting the stringent phase noise requirements.

An alternate solution of using an MZM based design was proposed and implemented by ASIAA with an aggressive schedule of delivering a completed engineering model within 18 months from inception (M. Chen, D. Kubo, H. Kiuchi - NAOJ).

Early development report:

https://www.dropbox.com/s/vxvzdubtpug4lny/ALS_presentation_2010feb21b.pdf?dl=0

ALMA downloads

Random collection of documents that I generated for the project. For some of these documents, you may be the first person to read it!

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.