About Me

My beginnings

I grew up in the rainy city of Seattle, where the winters were mostly spent indoors. Driven by boredom and curiosity, I was drawn towards exploring the inner workings of things in search of that eureka moment of discovery. One of my earliest memories is when a family friend gave me a set of tools, and I managed to remove the doorknobs in the house. I still get nervous replacing doorknobs today. My interest in electronics began at ten when my father purchased a pair of two-way radios. "Can you hear me? How about now?" This was well before the Verizon Wireless commercials. How did a small handheld device work over such distances? I was fortunate that my father was an avid reader, mostly of fiction, as he regularly took me to the Columbia Branch library and Shorey's Bookstore. These, along with other recollections from my childhood, are fond memories of simpler times.

Image taken with Lumix GF3 - Maunakea casting its own shadow during sunset, note the outlines of vehicles and UH-88 dome cast onto the nearby cinder cone

University of Washington, Boeing, NEC and TRW

I was raised in a working-class family who encouraged my sister and I to find work from an early age. After picking strawberries for two summers I ended up finding a part-time job working at Holly Park Greenhouse. Thereafter, I got a cushy job serving ice cream at Baskin Robbins on MLK Jr Way South. After high school, I worked as a teller for Seafirst Bank over the summer before I was off to the University of Washington. And while at the UW I worked as a copy machine operator in the evenings for Rainier Bank in the basement of the Rainier Tower building. I majored in electrical engineering and had a job lined up with Boeing Aerospace in Kent Space Center, courtesy of on-campus interviews. I had no idea what I was getting into and was assigned the task of designing an RF PCB to down-convert and digitize a radio signal from a Navy JTIDS terminal. This was also my first exposure to surface mount components and microstrip/stripline designs but fortunately, I had a good mentor (GWF). The engineering process of going from paper design to in-house circuit board fab and assembly, integration into chassis and racks, and then delivering to a Naval facility in San Diego (NOSC) was intense and at the same time appealing to me. It was fascinating stuff even thinking back today.

After 4 years at Boeing, I moved to Los Angeles to work for NEC America doing cell site maintenance and upgrades. And shortly afterwards, I ended up at TRW in Redondo Beach, California, courtesy of someone I used to work with at Baskin Robbins. It's strange how something seemingly innocuous such as scooping ice cream can change one's future. TRW was a great place to work and I also found Los Angeles to be a fun place to live while in my 20s and 30s. I worked with a group of modem engineers and we specialized in the development of high data rate satellite ground station receivers. These experiences at Boeing and TRW (now part of Northrop Grumman) were my formative years as an engineer and played an important part in who I am today. And for some inexplicable reason those earlier experiences, particularly at the greenhouse and copy center, have shaped me as a person as well.

Academia Sinica, Institute of Astronomy & Astrophysics

Fast forward to today, I am now working in the world of radio astronomy and live in the small rainy town of Hilo, Hawaii, population of 49,111 (2024). Going from industry to a research organization was a difficult transition for me but I've found that most academic organizations are of the accommodating sort. I've learned a lot of new things about astronomy and astronomical techniques that are not a normal part of communications. And like most things in life, the more I learn the more I know what I don't know. A big THANKS to the people who have and continue to share their knowledge with me, you know who you are. I'm blessed and thankful to still be doing something that I yearned to do as a child. I still take things apart to figure out their inner workings. After all, how many people can say that about their work?

Chief Engineer of Hawaii Operations

The ASIAA Hawaii office was established to support the SMA project on Maunakea* (~20% partnership with SAO) then later the AMiBA project on Maunaloa*, the GLT in Pituffik Space Base, Greenland (also partnered with SAO), and most recently the FRB project located in the south-east portion of the Big Island. As of this writing, we have a total of 7.5 individuals that are composed of 1 director, 1 scientist, 1 engineer (me), 1 software, 2 technicians (1 each for SMA & FRB projects), 0.5 IT (remote from Arizona), and 1 administrator. Not included in this tally are 1 engineer supporting the GLT from Taipei and 1 scientist supporting TAOS-2 from Philadelphia PA.

Whether you are interested in only one particular project or to get a general feel for what we do here at our ASIAA Hawaii office, I hope you find some of the descriptions interesting and informative. All photos in this site were taken by myself using either an iPhone 6/10/11 or Panasonic Lumix DMC-GF3, unless mentioned otherwise. Credits and acknowledgements for individuals working on particular items, in addition to myself, are provided in parentheses.

*Incidental note on the use of proper nouns Maunakea and Maunaloa. The mountain has been historically referred to as mauna kea and translates to mountain white in english. Similarly mauna loa translates to mountain long due to its shape. Here I've been using the proper names Maunakea and Maunaloa though they are often written as Mauna Kea and Mauna Loa elsewhere.

- Derek

System Designs

Instrument Designs

Instrument Designs

Though my role in system design is relatively infrequent, when involved I generally concentrate my early efforts working closely with scientists/system engineers toward developing an initial architectural system block diagram. Crude as it may be at this stage, it’s my attempt at laying out hardware solutions for others to scrutinize. From here, trades and compromises are made until we arrive at an architecture that is realizable within the constraints of the project. It’s analogous to design by committee and is rarely a smooth process that's full of ambiguity and personalities. But if done correctly can make a significant difference in the outcome of a project.

The GLT system design depicted above was developed in collaboration with my colleague, C.C. Han, in Taipei along with the science team which included M. Inoue, S. Matsushita, and K. Asada. We started from scratch in 2012 and iteratively evolved witan h increasing level of detail. As of this writing, we are on Rev-0V.

Instrument Designs

Instrument Designs

Instrument Designs

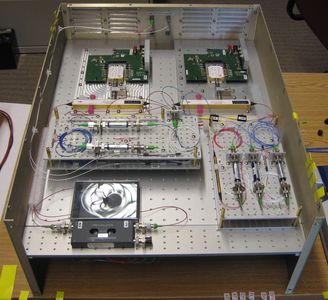

My favorite thing to work on, for better or worse, is with the development of custom instruments. I typically use a combination of circuit board designs and connectorized RF and/or optical components and integrate into a standalone EMI chassis. And more often than not, I end up doing the mechanical design and assembly which can often be an integral part of the units thermal and electrical performance. My aim is for clean and simple designs that are both functional and aesthetically satisfying to myself and the final end user (yes in that order). I don't consider myself an artist but this is one of my few creative outlets that I spend a lot time thinking through carefully with an eye toward craftsmanship. You can find out more about the instrument designs that I have been involved with by visiting the Projects at the top of this page.

The LO Reference Test Module shown above was developed for the ALMA project in collaboration with my engineering colleague, C.C. Han in Taipei. Software development was provided by R. Srinivasan. This was one of the more complex units I worked on at ASIAA and is described further in the ALMA Project section.

http://www.asiaa.sinica.edu.tw/gallery/show.php?i=d26da3f5e0870bf0e0d94e5ddec8598c

ASIAA Downloads

Below are old presentations I gave to the then ASIAA director, Dr. You-Hua Chu, during her visits to our Hawaii Office and describes a sampling of some of the work we did here. The 2014 file shows our organization chart with 14 full-time staff, double of what we are today.

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.